Ever wondered how electrical circuits are controlled with a simple switch? Relays are the key. These small devices make it possible to control high-power circuits with low-power signals.

In this post, we'll dive into what relays are, how they work, and why they're crucial in everything from industrial automation to home appliances.

You’ll learn about the different types of relays, their applications, and how they help protect and control electrical systems.

Relays operate on the principle of electromagnetic induction. When electrical current passes through the relay's coil, it creates a magnetic field. This field activates the armature, which moves and either opens or closes a contact, depending on the relay's design.

Electromagnetic induction is the process by which a coil of wire generates a magnetic field when an electrical current flows through it. This magnetic field attracts or repels the relay’s armature, which in turn opens or closes the contacts to control the connected circuit.

The coil generates the magnetic field, while the armature is the movable part that shifts in response. The armature connects or disconnects the relay's contacts, controlling the flow of current to a circuit.

When the relay's coil is energized, it pulls the armature toward the contact points. Depending on the relay type, the contacts can either open (if they were closed) or close (if they were open), completing or breaking the electrical circuit.

Coil (electromagnet): Generates a magnetic field when energized.

Contacts (NO, NC, and COM): Control the flow of current, either normally open (NO) or normally closed (NC).

Armature and yoke: The armature moves when the coil is energized, controlled by the yoke.

Spring mechanism: Returns the armature to its default position when the coil is de-energized.

Relays come in various types, each suited to different applications:

Electromechanical Relays (EMR): Commonly used for switching and amplifying electrical signals.

Solid-State Relays (SSR): Use semiconductor components to switch circuits without moving parts.

Reed Relays: A small, fast-relay type enclosed in a sealed glass tube.

Time-Delay Relays: Introduce a delay before the contacts change state.

High-Voltage Relays: Designed for controlling high-voltage circuits.

Safety Relays: Used in safety-critical systems, ensuring equipment is shut off during unsafe conditions.

Electromechanical Relays (EMR) use mechanical components to open and close contacts, and they are slower. They are durable but can wear out over time due to arcing at the contacts.

Solid-State Relays (SSR) are faster, more durable, and generate less heat. However, they may experience residual current leakage and require heat management.

Pros: Reliable in harsh conditions, easy to replace.

Cons: Prone to wear due to arcing, slower response time.

Pros: No moving parts, faster operation, no arcing.

Cons: Heat generation, potentially higher cost.

EMRs are best for applications requiring switching of high power, like motor control.

SSRs are ideal for applications that need fast switching and where arcing is a concern, like in precise control systems.

SPST (Single-Pole Single-Throw): A basic relay with two terminals. It can either open or close the circuit, but not both.

SPDT (Single-Pole Double-Throw): Can connect to one of two circuits. Ideal for switching between different paths.

DPST (Double-Pole Single-Throw): Similar to SPST, but controls two separate circuits.

DPDT (Double-Pole Double-Throw): Controls two circuits, and each can either be connected or disconnected.

An SPST relay has two contacts: one is normally open, and the other is normally closed. It can control a single circuit, either by completing or breaking the connection.

An SPDT relay has one common contact and two options (either NO or NC). This allows you to switch between two different circuits.

DPST: Works similarly to two SPST relays, each controlling a separate circuit.

DPDT: This relay allows control of two circuits with two options (like an SPDT relay for each circuit).

SPST: Used in simple on/off control applications.

SPDT: Common in toggle switches and motor direction controls.

DPST: Used for controlling two independent devices with one switch.

DPDT: Common in reversing motor applications or switching between two circuits.

Relays are used in various fields to control, protect, and automate electrical systems:

Industrial automation and control systems: Relays control machines, sensors, and actuators.

Relays in automotive systems: Used in starter motors, headlights, and alarm systems.

Relays in household appliances: Relays control temperature settings in washing machines and refrigerators.

Use in protection circuits: Relays are used to prevent overloads, short circuits, and other hazards.

In telecommunications, relays were once used to amplify signals in long-distance systems. They still play a role in modern communication devices for switching and protection.

In smart homes, relays help manage lighting, heating, and other systems through low-power control signals. They are key components in IoT devices like smart thermostats and security systems.

Isolation: Relays provide isolation between control and power circuits, protecting sensitive equipment.

Protection: They can detect faults and automatically disconnect power to avoid damage.

Simplifying systems: Relays allow for remote control of complex systems, like motors and lighting.

Relays can automatically shut down systems in the event of an overload, preventing expensive damage to machinery or wiring.

Contact wear: Over time, contacts can degrade due to the frequent opening and closing.

Arcing: This can cause damage to the contacts, especially in high-power applications.

Slower response: Mechanical movement can lead to delayed switching times.

Heat management: SSRs generate heat, which can affect performance if not properly managed.

Residual current leakage: Some SSRs may allow a small amount of current to flow even when turned off.

Voltage and current ratings: Ensure the relay matches the power requirements of your system.

Contact type: Choose between NO, NC, or a combination based on your needs.

Environmental conditions: Consider temperature, humidity, and potential exposure to contaminants.

Choose SSRs for faster switching, quieter operation, and durability. EMRs are better for high-power, industrial applications.

Use a multimeter to test the relay's coil and contact continuity. Check for continuity between NO and NC contacts.

Regularly check for wear and replace relays when the contacts show signs of damage or failure.

Prevent arcing by using snubber circuits.

Ensure proper installation to avoid overheating.

Use proper fuses to protect relays from excessive current.

Relays are generally used for smaller current applications, while contactors are designed for high-current circuits.

Relays can switch both AC and DC circuits depending on their design and ratings.

Mechanical relays last around 10,000 to 100,000 operations, while solid-state relays can last much longer, depending on usage.

Relays are essential electrical components that control circuits using low-power signals. They work by creating a magnetic field when energized, activating contacts to open or close. There are different types of relays, including electromechanical and solid-state, each suited for specific applications. Relays provide crucial benefits like circuit isolation, protection, and remote control of high-power systems. They are used in various industries, from automation to household appliances, ensuring safe and efficient operations.

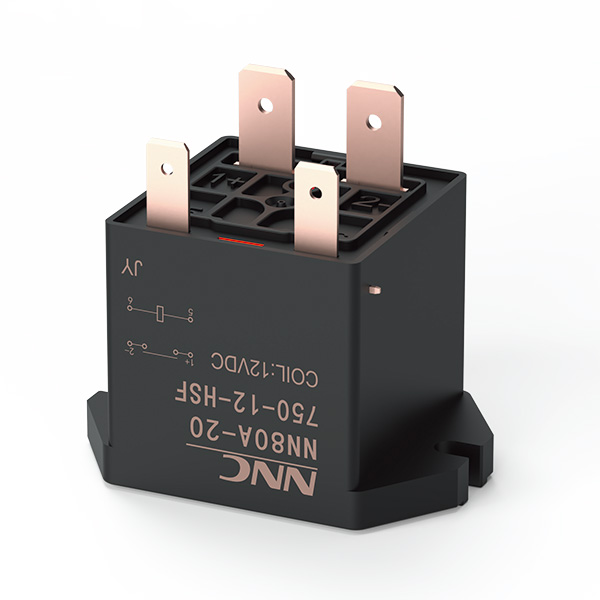

Xinling Electric is a leading manufacturer specializing in high-quality relay products. The company stands out for its strong production capacity, operating with efficient automation systems that ensure both flexibility and scalability. Xinling Electric maintains strict quality control from raw materials to finished products, ensuring excellent durability and performance. Their commitment to technological innovation continuously drives the development of energy-saving and efficient solutions for diverse industries.

With an adaptable production mode and a focus on customer needs, Xinling Electric ensures timely deliveries and high standards in every product. Their relays are widely used across sectors including industrial control, automotive, new energy, smart homes, and medical equipment, highlighting their versatility and contribution to various applications.