Views: 0 Author: Site Editor Publish Time: 2025-05-21 Origin: Site

Are you confused about the differences between a micro switch and a limit switch? You’re not alone. These two types of switches are often used in similar applications, but they serve very different purposes.

In this post, we’ll discuss the unique functions of micro switches and limit switches. You'll learn how each works and where they are commonly used in various industries and everyday devices.

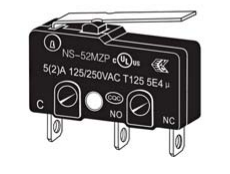

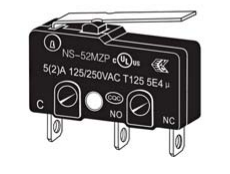

Micro switches: These are compact and miniaturized. They're designed to fit into tight spaces like appliances or small electronics.

Limit switches: These are larger and more rugged. They are built for industrial environments and can handle heavier machinery.

Micro switches: Known for their quick action and sensitivity, these switches require minimal force to activate. They are great for

applications that need instant feedback.

Limit switches: These switches have mechanical triggers, such as levers or rollers. They detect an object’s position by physical contact, providing a more deliberate activation.

Micro switches: They are designed to last for millions of cycles, especially in low to moderate current applications.

Limit switches: These switches are more rugged and can handle rougher environments, but they tend to have fewer cycles than micro switches due to their heavier-duty construction.

Micro switches: These are typically used in lower voltage settings (less than 250V AC) and lower current ratings.

Limit switches: These can handle much higher currents and voltages, up to 600V AC, making them ideal for industrial machines and heavy-duty equipment.

Household appliances: Micro switches are used in various appliances, including sliding window installation. They help ensure smooth and secure operation by detecting movement or position.

Automotive systems: These switches are in car door sensors, seat belt mechanisms, and other safety features.

Industrial equipment: Micro switches play a critical role in automation, medical devices, and robotics by providing quick and precise control.

Industrial machinery: Limit switches are widely used in CNC machines, conveyor belts, and other automated equipment for position detection.

Transportation: Elevators, hoists, and automated doors rely on limit switches for safe, precise control of movement.

Heavy-duty applications: Cranes, robotic arms, and factory automation systems require robust limit switches to ensure reliability and safety.

Project size and environment: If your project involves smaller devices or home use, a micro switch is likely better. Limit switches are ideal for industrial machinery or larger applications.

Sensitivity: Micro switches offer high sensitivity, providing immediate action, whereas limit switches are more focused on precise mechanical movements.

Power and voltage needs: Micro switches work well with low-voltage, low-current systems. If your project demands higher current handling, a limit switch is more suitable.

Micro switches: These are ideal for home installations, like sliding window installation. They ensure smooth operation and safety in tight spaces.

Limit switches: While they can be used in window systems, they’re more commonly found in heavy-duty automated systems.

Compact and ideal for small devices.

High sensitivity for quick and precise feedback.

Easy installation and generally more cost-effective than limit switches.

Best for low-current, low-voltage applications.

Susceptible to external interference, especially in harsh environments.

Durable and can withstand tough conditions.

Can handle high current and voltage, making them suitable for industrial machinery.

Provide reliable position control in complex systems.

Larger and less suitable for tight spaces.

Installation can be more complex due to their rugged design.

Less sensitive compared to micro switches, which could be a limitation in certain applications.

A: A micro switch is smaller, more sensitive, and typically used in low-voltage applications, while a limit switch is more rugged and designed for heavy-duty industrial uses.

A: Micro switches can replace limit switches in consumer electronics or home appliances, but limit switches are preferred for high-power or industrial environments due to their durability and ability to handle larger voltages and currents.

A: Micro switches last longer, often capable of millions of cycles, while limit switches have a shorter lifespan due to the mechanical force required for their operation.

A: Limit switches are triggered by mechanical contact with an object, such as a lever, plunger, or roller, activating the electrical circuit.

A: Limit switches can be used for sliding window installation, but micro switches are typically better for home use due to their compact size and sensitivity.

A: Micro switches are sensitive to dust, moisture, and electromagnetic interference, which can affect their performance in harsh industrial environments.

A: Yes, micro switches are generally more cost-effective due to their smaller size and simpler design.

Micro switches offer several benefits, including their compact size, cost-effectiveness, and high sensitivity, making them ideal for small devices and household appliances. On the other hand, limit switches are known for their durability, ruggedness, and ability to handle high currents, which makes them perfect for industrial machinery and heavy-duty applications.

When deciding which switch to use, consider the nature of your project. Micro switches are better suited for home appliances and smaller electronic systems, while limit switches are more reliable for industrial settings, where precision and durability are key.