Views: 0 Author: Site Editor Publish Time: 2025-05-16 Origin: Site

Relays play a key role in electrical systems, especially in vehicles. Without proper testing, a faulty relay can disrupt essential functions.

In this post, we’ll explain how to test a relay effectively, particularly a 40A relay. You’ll learn how to identify common issues and troubleshoot them with easy-to-follow methods.

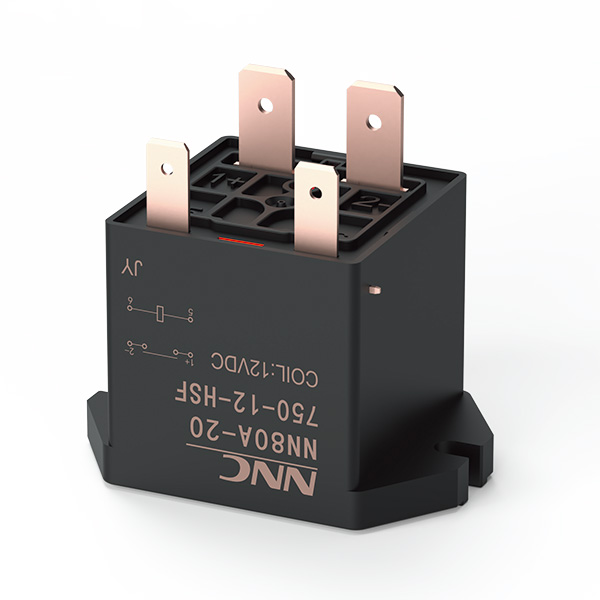

40A Relay (or a relay suitable for your system)

9-Volt or Car Battery

18-Gauge Wire (to connect the battery and relay)

Multimeter (for continuity and resistance tests)

Electrical Connectors (optional for better connections)

Knowledge of Relay Pin Numbers (important for correct pin identification)

Always disconnect power before testing.

Wear safety gear such as gloves and goggles.

Work in a well-ventilated area, especially if dealing with car batteries.

Relays use an electromagnetic coil to open or close switches within a circuit. The coil is energized by applying voltage to certain pins, allowing the relay to control high-power components using a low-power signal.

Pins 85 and 86: Coil terminals.

Pins 87 and 30: Switch terminals.

Current flows through pins 86 and 85, creating an electromagnet that moves a metal arm to connect pins 87 and 30, completing the circuit.

SPST (Single Pole Single Throw): Simple on/off switch.

SPDT (Single Pole Double Throw): Allows for more complex switching, offering more options for control.

Relays are commonly used in:

Vehicles: For controlling headlights, cooling fans, and other components.

Home Appliances: For turning on/off high-power devices like motors.

Industrial Systems: Used for automation and controlling machinery.

Locate the Relay and Identify Pins 85 and 86

Find your relay in the circuit and identify pins 85 and 86. These are the coil terminals.

Set Up Your Car Battery

Ensure the car’s battery is disconnected from the vehicle's electrical system. You’ll use the battery to power the relay.

Connect the Wires

Connect one wire to the positive terminal of the battery and the other to pin 86. The second wire should connect to the negative terminal and pin 85.

Observe the Relay Click

When connected, the relay should make an audible "click," indicating that the internal switch has closed. This confirms the relay is working.

The 12V from your car battery simulates the normal operating environment of a relay in a vehicle, allowing you to easily test its function.

Prepare the 9-Volt Battery

Connect the positive terminal of the 9-volt battery to pin 86, and the negative terminal to pin 85.

Observe the Relay Click

When you touch both terminals to the relay pins, you should hear a click. This means the relay is working as expected.

A 9-volt battery is low power, making it a safe and easy way to test smaller relays without the risk of damaging the relay or your circuit.

Set the Multimeter to Measure Resistance (Ohms)

Set your multimeter to the "Ohms" setting to check for continuity.

Measure Resistance Between Pins 85 and 86

Test the resistance between pins 85 and 86. A healthy relay will typically show a reading between 50-120 ohms.

Test the Switch Pins (87 and 30)

Next, test between pins 87 and 30. If the relay is off, there should be no continuity. If there is, the relay might be stuck closed.

Energize the Relay and Test Continuity

Apply 12V to pins 85 and 86 and check the resistance between pins 87 and 30 again. A click should confirm the relay is working and the switch is closed.

Verify the Voltage Across the Switch Pins

Finally, verify that the voltage is consistent across the switch pins to ensure the relay is delivering proper power to the circuit.

Using a multimeter helps you verify the health of both the coil and switch terminals. It ensures that your relay isn’t just clicking, but also functioning correctly under load.

Xinling Electric stands out as a leading electromagnetic relay manufacturer, driven by its strong production capabilities, advanced technology, and commitment to quality. With over 25,000㎡ of plant space and a production capacity exceeding 200,000 units daily, Xinling Electric is equipped to meet large-scale demands while maintaining flexibility for customized solutions. The company boasts high reliability in its products, ensuring long-lasting performance and adherence to strict quality standards. Continuous technological innovation, including investments in green technologies, supports the company’s mission to promote energy efficiency and sustainable development. Backed by decades of experience, Xinling Electric combines industry expertise with a customer-first philosophy to deliver tailored, efficient solutions that meet diverse market needs.

If your relay isn’t clicking:

Check Connections: Ensure all wiring is secure.

Damaged Coil: Use a multimeter to check for continuity in the coil. A damaged coil will show no continuity.

A relay stuck open or closed will fail to function properly:

Check Resistance: Measure resistance between the switch pins. If it reads continuously, it’s stuck.

Replace the Relay: A faulty relay often needs to be replaced to fix this issue.

Overheating can be caused by excessive current or poor connections:

Use Correct Current Ratings: Ensure the relay matches the specifications for your circuit.

Inspect Connections: Loose or corroded connections can lead to excessive heating.

If you discover your relay is faulty, follow these steps:

Remove the Old Relay: Disconnect it from the circuit.

Install the New Relay: Ensure you place the new relay in the correct orientation and reconnect it properly.

Solid-state relays don’t have moving parts but can still fail. Use a multimeter in diode test mode to verify their functionality.

If removing the relay isn’t feasible, use the same methods while the relay remains in the circuit, testing for continuity and voltage directly at the terminals.

A: A relay controls the flow of electricity by opening or closing a circuit, while a fuse protects the circuit by breaking the connection when there is excess current.

A: Yes, you can test a relay in-circuit using methods like checking continuity with a multimeter or applying voltage to the relay coil while monitoring the switch.

A: Test relays annually or if you experience malfunctioning components. Regular checks help maintain the overall health of your electrical system.

Testing a relay can be done using a car battery, 9-volt battery, or a multimeter. Each method helps ensure the relay is functioning properly.

Regular testing is essential to prevent electrical issues.

If basic testing doesn’t resolve the problem, it’s time to seek professional help.