Views: 0 Author: Site Editor Publish Time: 2025-05-16 Origin: Site

Solid state relays (SSRs) are vital components in modern electrical systems, particularly for applications requiring fast and reliable switching. Unlike traditional mechanical relays, which rely on physical contacts to open and close circuits, solid state relays utilize electronic components to perform the same task with greater precision and durability. In this article, we will explore how solid state relays work, their advantages, and the applications they are suited for.

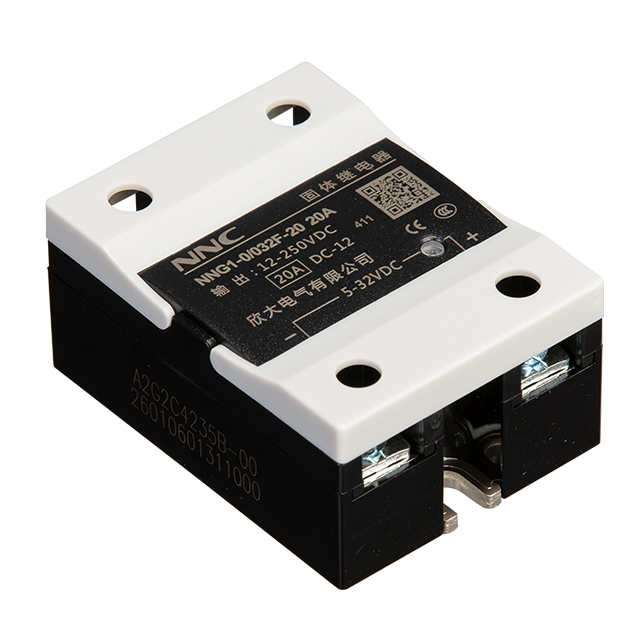

A solid state relay is an electronic switching device that uses semiconductor components such as thyristors, triacs, or triode for alternating current (AC) to control the operation of an electrical circuit without moving parts. SSRs allow for smooth and silent operation, offering high-speed switching and reliability. Unlike mechanical relays, SSRs don’t have physical contacts that wear out over time, making them more durable and long-lasting.

The working principle of a solid state relay can be summarized in the following steps:

Control Signal: A low-power control signal, usually in the form of voltage, is applied to the input of the SSR. This signal can come from various sources, such as a microcontroller or a control circuit.

Triggering: When the input signal is applied, it activates the semiconductor inside the SSR. In the case of an AC SSR, this could be a triac or a thyristor. The semiconductor component becomes conductive, allowing current to flow through the load.

Switching: Once triggered, the SSR remains in the "on" state until the input signal is removed or the system reaches a predetermined threshold. The relay switches without any physical movement, providing a faster, quieter, and more reliable method of control.

Output Control: The SSR’s output controls the high-power circuit or device. The load can be anything from a light bulb, motor, or heater, depending on the application. The SSR ensures that the high-power circuit is switched on or off based on the low-power control signal.

There are several types of solid state relays, each designed to handle different applications and provide varying levels of control:

AC Solid State Relays (AC SSRs): These are designed to control alternating current (AC) loads. They use semiconductor components such as triacs or thyristors to switch the load.

DC Solid State Relays (DC SSRs): These are used for controlling direct current (DC) loads. Typically, they use components such as MOSFETs or IGBTs.

Zero-Crossing SSRs: These SSRs are designed to switch at the moment when the AC waveform crosses zero volts. This reduces the inrush current, making it ideal for controlling inductive loads like motors and transformers.

Phase-Control SSRs: These allow for precise control of the timing and duration of power supplied to the load, making them ideal for controlling heating elements or dimming lights.

One of the major advantages of solid state relays is their durability. Since they have no moving parts, there is little wear and tear over time. This makes them ideal for environments where mechanical relays would quickly fail due to contact degradation.

SSRs can switch on and off much faster than mechanical relays, which is crucial in high-speed automation systems. This rapid switching also reduces the overall power loss and increases the system's efficiency.

Solid state relays operate without any mechanical movement, which means they function silently. This is especially important in applications where noise is a concern, such as in residential or laboratory environments.

SSRs are more reliable than mechanical relays, as they do not suffer from contact arcing, which can cause failures in traditional relays. This reliability is critical in industrial and safety applications where failure is not an option.

Without the need for bulky mechanical parts, solid state relays can be made much smaller and lighter than their mechanical counterparts. This is particularly useful in modern electronic designs where space and weight are at a premium.

Solid state relays are typically more resistant to temperature fluctuations, making them ideal for harsh environments such as industrial settings, automotive applications, and even outdoor use.

Solid state relays are used in a variety of applications, thanks to their reliability, fast switching, and silent operation. Some of the common applications include:

SSRs are widely used in industrial automation systems for controlling motors, conveyors, and other machinery. Their fast switching and durability make them ideal for high-cycle applications.

SSRs are commonly used in lighting control systems, especially for dimming applications and stage lighting. Their ability to control the timing and intensity of lighting provides greater flexibility in design.

In heating systems, SSRs are used to regulate the temperature by controlling heating elements. Phase-control SSRs, in particular, allow for precise temperature control, making them essential in ovens, furnaces, and other heating equipment.

Many modern home appliances, such as washing machines, dishwashers, and microwave ovens, utilize solid state relays to manage switching between various components within the system.

Solid state relays are also found in communication equipment for controlling signal flow. Their fast response time is crucial in maintaining high-quality signals.

At Xinling Electric, we specialize in providing high-quality solid state relays for various industrial and commercial applications. Our SSRs are designed with the latest semiconductor technology to offer the best in reliability, speed, and energy efficiency. Whether you are looking for SSRs for automation, temperature control, or other applications, our products are built to meet the rigorous demands of modern electrical systems.

With a focus on performance, durability, and cost-effectiveness, Xinling Electric’s solid state relays are the perfect choice for businesses looking to optimize their electrical systems. Our commitment to quality ensures that you will receive a product that not only performs to expectations but also exceeds industry standards.

A: The main difference lies in the operation mechanism. SSRs use semiconductors to switch circuits, while mechanical relays rely on physical moving contacts. This gives SSRs advantages in speed, durability, and silent operation.

A: Yes, solid state relays are available in configurations that can handle high voltages. Depending on the model, they can manage both low and high-voltage applications, including up to several hundred volts AC or DC.

A: Because SSRs have no moving parts, they can last much longer than mechanical relays. With proper maintenance, they can last several years, especially in clean, controlled environments.

A: Yes, solid state relays are ideal for motor control, particularly for systems requiring fast and reliable switching. Zero-crossing SSRs are specifically designed to handle inductive loads like motors.

A: Consider factors such as the type of load (AC or DC), voltage, current rating, and switching frequency. It’s also important to select the appropriate control voltage and switching speed for your application.

Solid state relays are an essential component in modern electrical systems, offering numerous advantages over traditional mechanical relays, such as faster switching, higher durability, and silent operation. They are widely used across a variety of industries, including automation, lighting control, and temperature regulation. Xinling Electric’s range of solid state relays is designed to meet the growing demands of industries seeking reliable, efficient, and cost-effective solutions.

By investing in high-quality solid state relays, businesses can enhance the performance and longevity of their systems. For more information on our solid state relays and other electrical components, feel free to contact Xinling Electric today.