Clion P69F05E1 for NNC69K(TL) 14FT-1Z High Reliability Relay Socket for Industrial Control

Use the Clion P69F05E1 for NNC69K(TL) 14FT-1Z High Reliability Relay Socket in demanding electrical control applications. It supports high current carrying capacity for reliable performance in industrial setups.

This relay socket features electrical switching capability that ensures consistent operation. It handles heavy loads and fits different relay modules for flexible designs.

The relay socket allows timing control function, which expands system flexibility. It enhances industrial automation and energy equipment by integrating smoothly with control circuits.

Its high reliability ensures stable performance under high current conditions. It uses heat-resistant and flame-retardant materials to support safe operation.

The relay socket fits standard DIN rail mounting, making it easy to install in industrial cabinets and panels.Choose this high current carrying capacity relay socket for HVAC, power distribution, and renewable energy systems. It is an essential choice for users looking for a relay socket manufacturer that delivers reliable products.

Technical Specifications

| Parameter | Value |

| Model | P69F05E1 |

| Brand | CLION ELECTRIC |

| Rated Current | 16A |

| Rated Voltage | 300V |

| Dielectric Strength | 4000V/S |

| Operating Temperature | -40°C ~ 7°C |

| Housing Material | Flame-retardant PA46-S250F6(V0) |

| Clamp Material | QSN6.5-0.1 |

| Mounting | Standard DIN rail |

| Accessories | None |

| Weight | Approx. 28g/piece |

| Packaging | 500pcs/box, Gross: 15kg, Net: 14kg, Size: 42.5×34.4×32.5 cm |

Choose the Clion P69F05E1 for NNC69K(TL) 14FT-1Z High Reliability Relay Socket to improve system stability and reduce maintenance in high current applications.

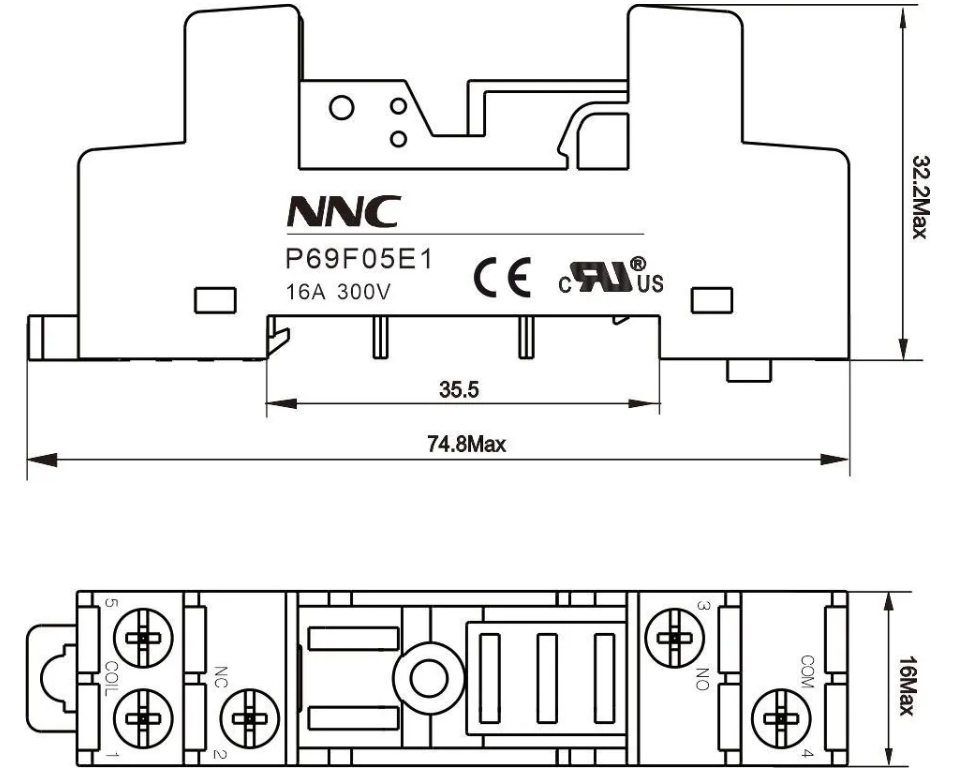

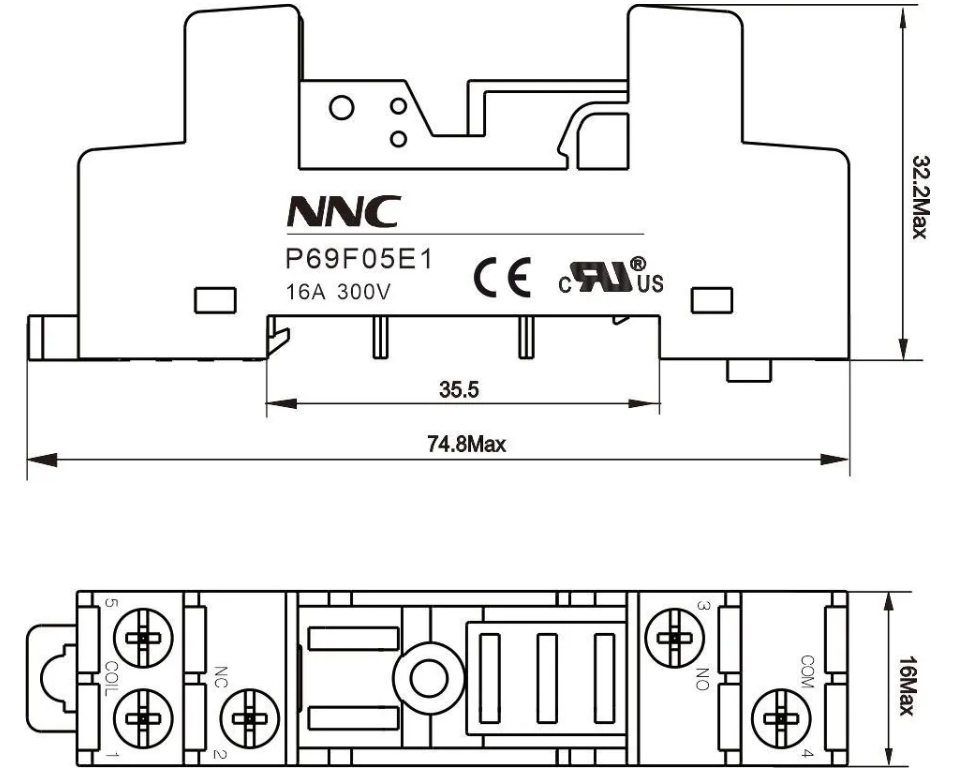

Wiring Diagram

Features and Applications of Clion P69F05E1 High Reliability Relay Socket

High Current Capacity for Industrial Control

This high reliability relay socket supports heavy current loads up to industrial standards. It’s ideal for applications requiring solid state relay solutions with high current carrying capacity, ensuring stable electrical switching in power distribution and automation systems.

Advanced Electronic Overload Protection for Safety

Equipped with fast-response electronic overload protection, this relay socket detects overcurrent quickly to prevent equipment damage. It enhances system reliability in industrial automation, renewable energy systems, and manufacturing plants.

Thermal Magnetic Breaker for Dual Protection

Combining thermal and magnetic protection, this relay socket guards against overloads and short circuits. It’s a trusted component in industrial relay socket assemblies used in HVAC controls, motor drives, and critical power systems.

Heat-Sensing Technology to Prevent Thermal Damage

The integrated heat-sensitive protection monitors temperature changes and prevents overheating. This feature is valuable in applications like smart grid technology, packaging equipment, and electrical control panels requiring durable relay sockets.

Flexible Timing Control Functions for Automation

Supports timing control functions that allow precise operation sequences. It enhances control in lighting systems, automated machinery, and energy management solutions, making it a versatile choice for reliable relay socket suppliers.

Easy Installation with Standard DIN Rail Compatibility

Designed for quick and secure mounting on standard DIN rails, this relay socket facilitates easy integration in existing industrial setups and new projects. Its compatibility makes it a preferred option for relay socket manufacturers serving diverse industries.

By choosing this high reliability relay socket, you get a robust solution suitable for high current switching, reliable overload protection, and flexible timing control, meeting the demands of modern industrial and energy applications.

FAQs

Q1: What factors should I consider when selecting a solid state relay?

A1: You should consider load type, voltage and current ratings, control voltage, and switching speed to match your application needs.

Q2: How do solid state relays improve system reliability?

A2: They eliminate mechanical wear, reduce electrical noise, and provide faster switching for longer equipment life.

Q3: Can solid state relays be used for both AC and DC loads?

A3: Many solid state relays are designed to handle both AC and DC loads, but it’s important to check specifications for your exact needs.

Q4: What causes a solid state relay to fail prematurely?

A4: Overheating, incorrect load specifications, poor heat dissipation, and voltage spikes are common causes of failure.

Q5: How is heat managed in solid state relays during operation?

A5: Proper heat sinks and ventilation are essential to dissipate heat generated during switching and prevent damage.

Q6: Are solid state relays suitable for switching inductive loads?

A6: Yes, but special attention is needed to select relays rated for inductive loads to avoid damage and ensure performance.

Q7: What maintenance is required for solid state relays?

A7: They require minimal maintenance, mostly regular inspection for heat sink condition and secure wiring connections.

注: 建议图片大小150px*50px

注: 建议图片大小150px*50px