ESL4ND

Esinctrl

| Availability: | |

|---|---|

| Quantity: | |

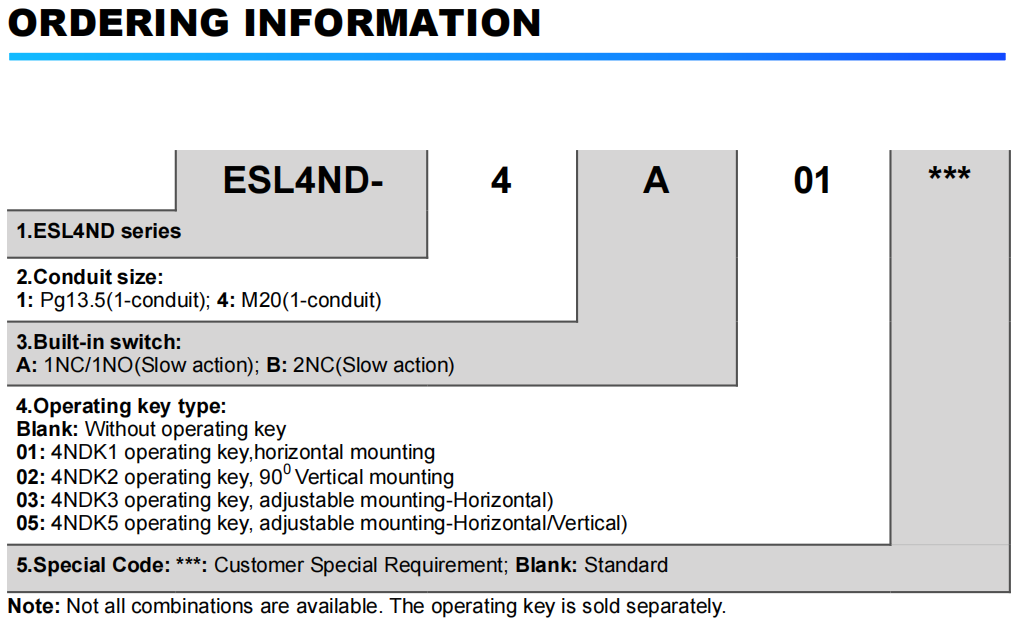

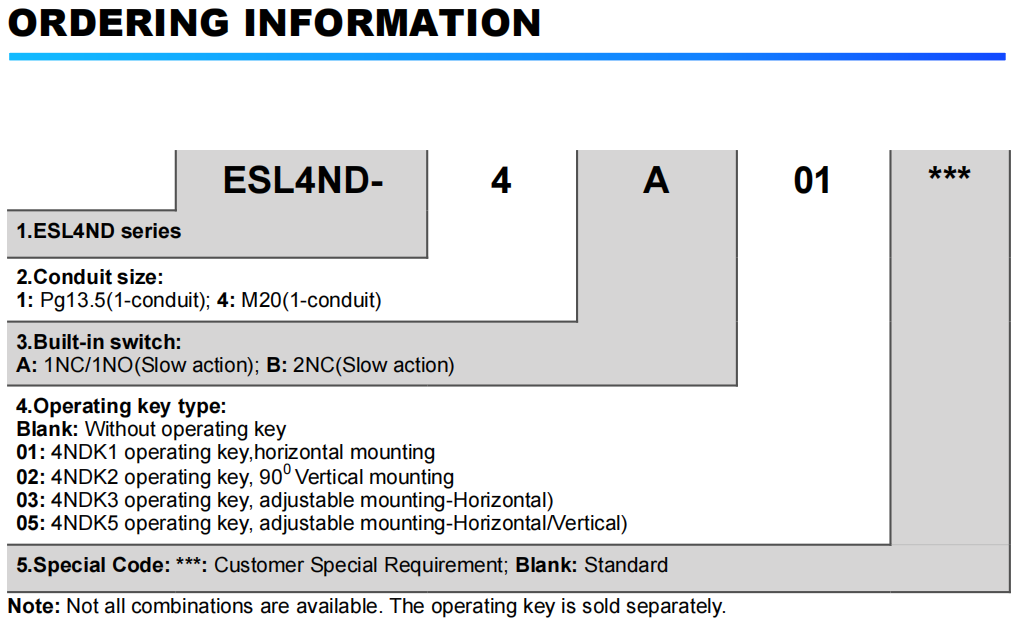

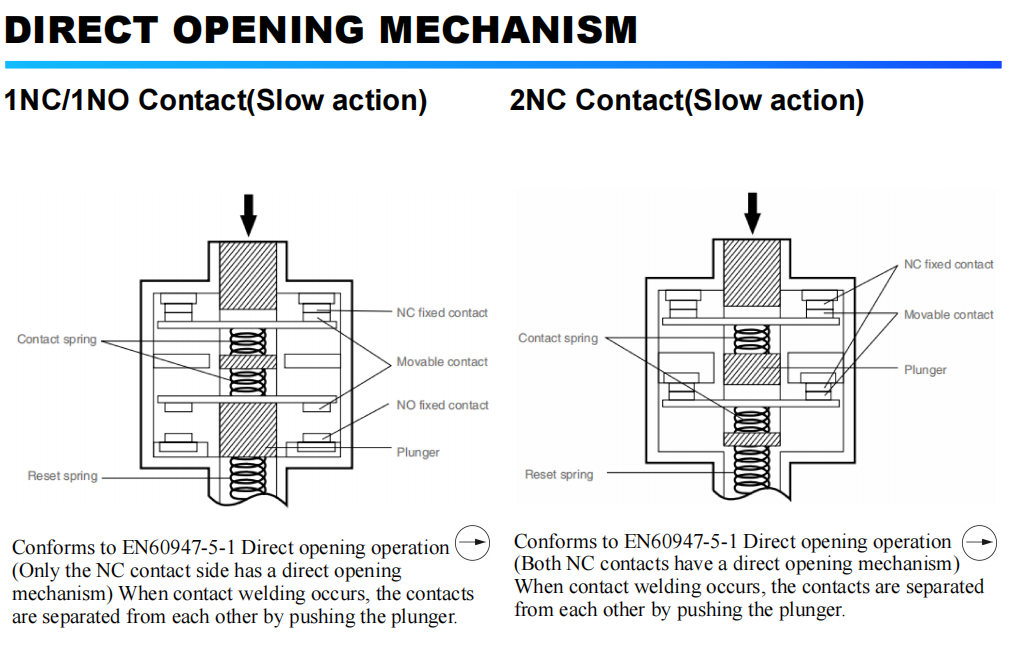

The ESL4ND limit switch series offers two contact combinations—1NC/1NO and 2NC—enabling flexible implementation of safety interlocking and signal feedback functions within the same housing.

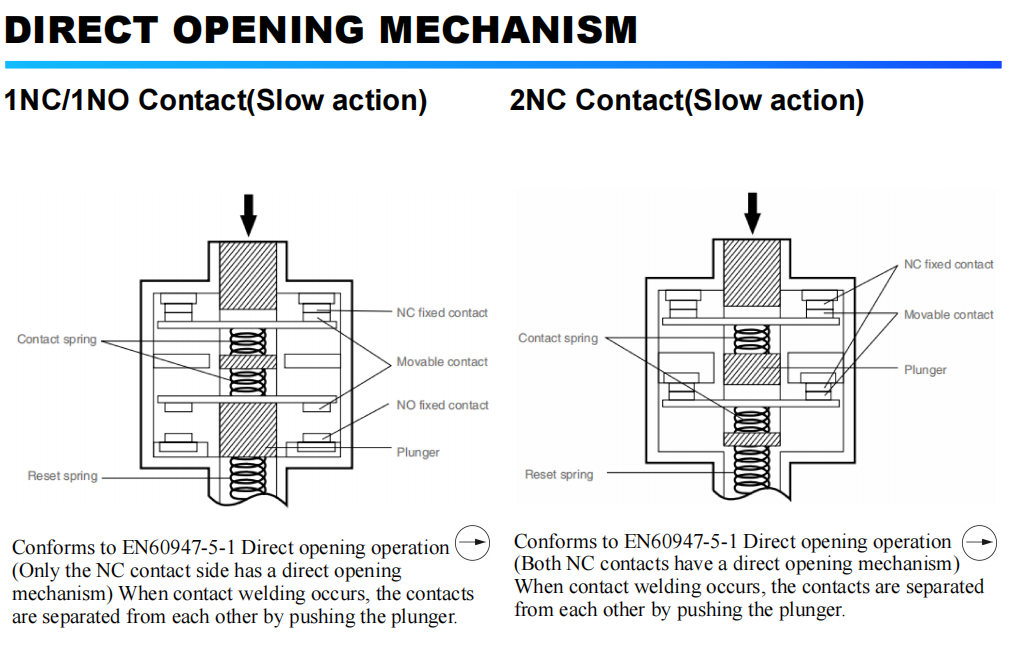

Its “direct break” mechanism complies with the mandatory disconnection requirements of EN 60947-5-1—even if the contacts are welded, they reliably separate instantly when the actuator is applied, ensuring personnel and equipment safety.

Multiple operating keys (plunger, roller, rocker arm, etc.) cover linear, rotary, and multi-directional triggering scenarios, making installation and commissioning more convenient.

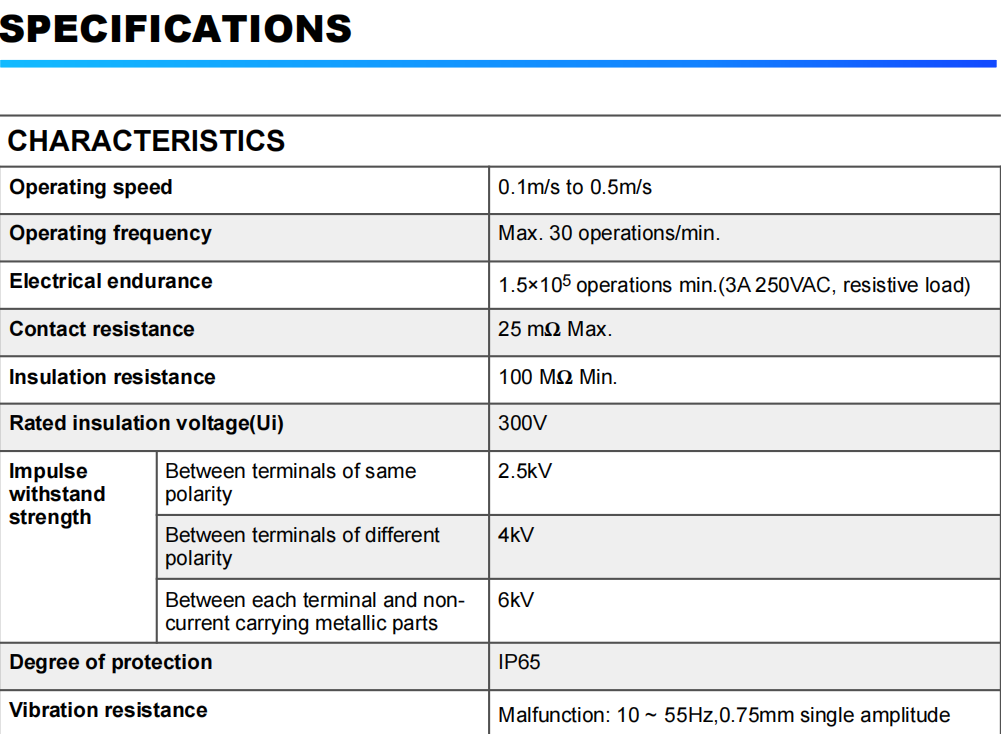

The IP65-rated fully sealed structure ensures stable operation in dusty, misty, and oily environments, while the low contact resistance of ≤25 mΩ effectively suppresses heat generation and energy consumption, providing precise and durable position detection solutions for high-frequency, long-life industrial automation systems.

1. Automated production lines

CNC machine tools, robot workstations: Detect the arrival signals of slides, fixtures, and protective doors to ensure safe start and stop of the machining cycle.

2. Logistics and lifting equipment

Stacker cranes for stereoscopic warehouses and elevators for conveyor lines: Confirm that the loading platforms or pallets have reached the target levels.

3. New energy and Electricity

Wind turbine generator set: Confirmation of the 0°/90° position of the pitch system blades; The cabin vibrates greatly. The forced disconnection mechanism ensures the reliable separation of the contacts.

The ESL4ND limit switch series offers two contact combinations—1NC/1NO and 2NC—enabling flexible implementation of safety interlocking and signal feedback functions within the same housing.

Its “direct break” mechanism complies with the mandatory disconnection requirements of EN 60947-5-1—even if the contacts are welded, they reliably separate instantly when the actuator is applied, ensuring personnel and equipment safety.

Multiple operating keys (plunger, roller, rocker arm, etc.) cover linear, rotary, and multi-directional triggering scenarios, making installation and commissioning more convenient.

The IP65-rated fully sealed structure ensures stable operation in dusty, misty, and oily environments, while the low contact resistance of ≤25 mΩ effectively suppresses heat generation and energy consumption, providing precise and durable position detection solutions for high-frequency, long-life industrial automation systems.

1. Automated production lines

CNC machine tools, robot workstations: Detect the arrival signals of slides, fixtures, and protective doors to ensure safe start and stop of the machining cycle.

2. Logistics and lifting equipment

Stacker cranes for stereoscopic warehouses and elevators for conveyor lines: Confirm that the loading platforms or pallets have reached the target levels.

3. New energy and Electricity

Wind turbine generator set: Confirmation of the 0°/90° position of the pitch system blades; The cabin vibrates greatly. The forced disconnection mechanism ensures the reliable separation of the contacts.