ESL4N

Esinctrl

| Availability: | |

|---|---|

| Quantity: | |

ESL4N is specifically designed for high reliability and high-speed applications. Its Direct Opening Structure (forced disconnection structure) ensures instantaneous separation of contacts in the event of welding or failure, further enhancing safety levels.

Three contact configurations (1NC/1NO,2NC,2NC/1NO,3NC) offer flexible compatibility with control logic, meeting diverse safety interlock requirements.

The product fully complies with the EN60947-5-1 standard, with electrical performance and mechanical lifespan rigorously validated; its IP67 protection rating ensures it remains rock-solid even in environments with oil mist, dust, or short-term immersion.

Thanks to an optimized transmission mechanism, the ESL4N supports high operating speeds, enabling millisecond-level precise positioning detection even in high-speed reciprocating motion applications.

It is an ideal choice for applications requiring both safety and high-speed performance, such as machine tools, robots, and lithium-ion battery equipment.

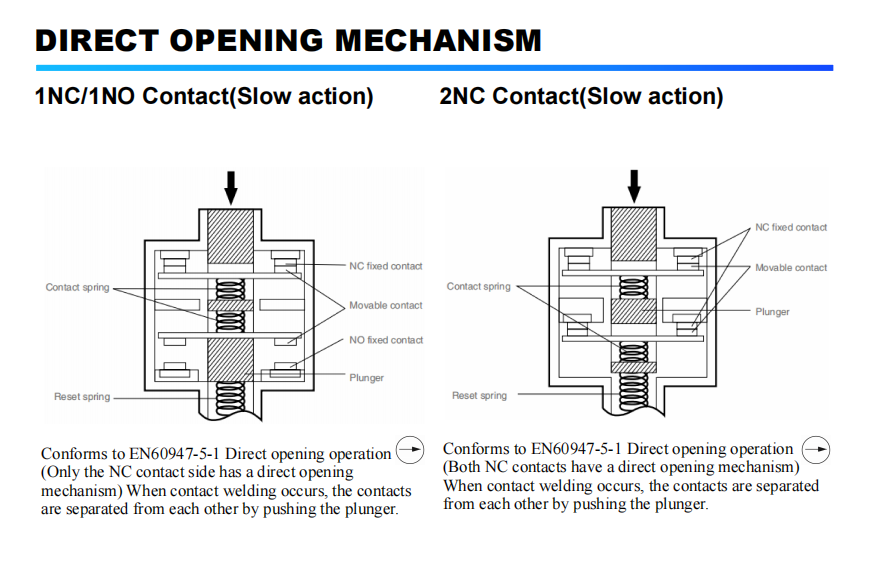

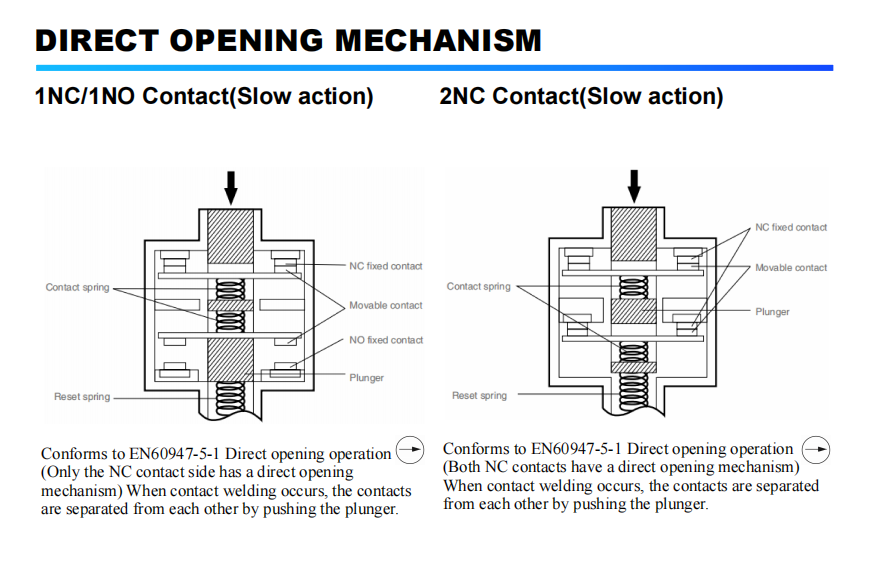

The Direct Opening Structure (forced break mechanism) of ESL4N forces the normally closed (NC) contact apart by a mechanical plunger when the NC contact is welded, ensuring that the NC circuit is reliably broken and thus achieving fault safety.

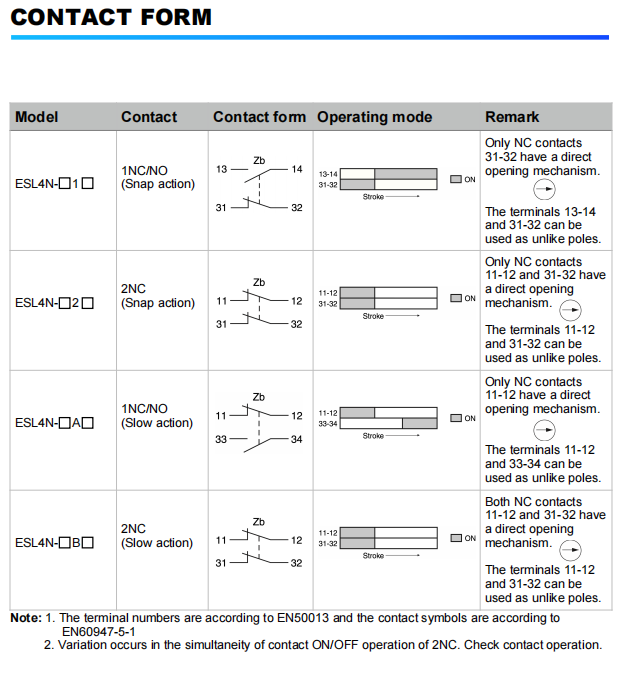

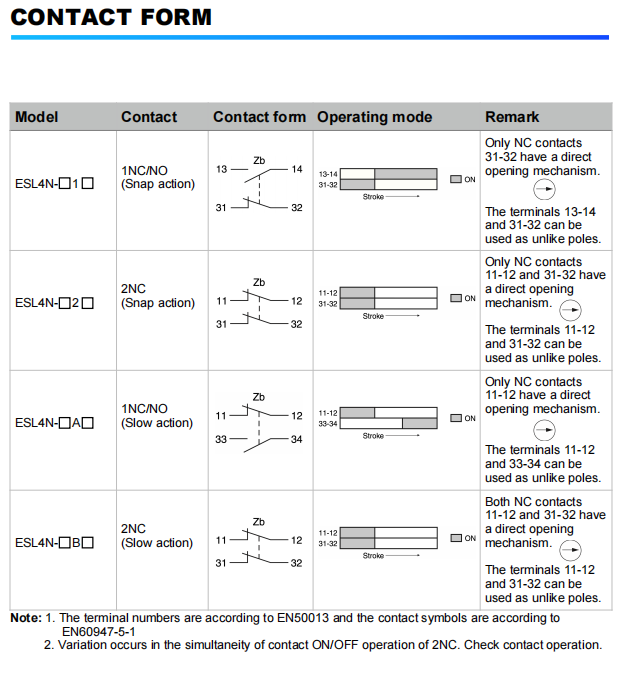

1NC/1NO (Snap/Slow) — Only NC contacts (31-32 or 11-12) have a forced break function.

2NC (Snap/Slow) — Both sets of NC contacts (11-12 and 31-32) have a forced break function.

2NC/1NO, 3NC (Slow) — All NC contacts have a forced break function.

The NO side of the open contact is not designed with a forced disconnection mechanism. This mechanism complies with the “direct disconnection operation” requirements of EN 60947-5-1 and must meet the test standards for minimum direct disconnection travel (DOT 3.2–5.8 mm) and minimum direct disconnection force (DOF 20 N).

ESL4N is specifically designed for high reliability and high-speed applications. Its Direct Opening Structure (forced disconnection structure) ensures instantaneous separation of contacts in the event of welding or failure, further enhancing safety levels.

Three contact configurations (1NC/1NO,2NC,2NC/1NO,3NC) offer flexible compatibility with control logic, meeting diverse safety interlock requirements.

The product fully complies with the EN60947-5-1 standard, with electrical performance and mechanical lifespan rigorously validated; its IP67 protection rating ensures it remains rock-solid even in environments with oil mist, dust, or short-term immersion.

Thanks to an optimized transmission mechanism, the ESL4N supports high operating speeds, enabling millisecond-level precise positioning detection even in high-speed reciprocating motion applications.

It is an ideal choice for applications requiring both safety and high-speed performance, such as machine tools, robots, and lithium-ion battery equipment.

The Direct Opening Structure (forced break mechanism) of ESL4N forces the normally closed (NC) contact apart by a mechanical plunger when the NC contact is welded, ensuring that the NC circuit is reliably broken and thus achieving fault safety.

1NC/1NO (Snap/Slow) — Only NC contacts (31-32 or 11-12) have a forced break function.

2NC (Snap/Slow) — Both sets of NC contacts (11-12 and 31-32) have a forced break function.

2NC/1NO, 3NC (Slow) — All NC contacts have a forced break function.

The NO side of the open contact is not designed with a forced disconnection mechanism. This mechanism complies with the “direct disconnection operation” requirements of EN 60947-5-1 and must meet the test standards for minimum direct disconnection travel (DOT 3.2–5.8 mm) and minimum direct disconnection force (DOF 20 N).