Micro Switch NS

CLION

| Availability: | |

|---|---|

| Quantity: | |

The 2 mm Contact Gap Three Split Springs Hinge Roller Lever Micro Switch (model series: NS-102MGP/NS-52MGP) is a high-precision electromechanical switching component produced by CLION. It integrates a hinge roller lever structure, 2mm standard contact gap and three split springs design. The product is engineered to deliver stable and accurate on-off control for electrical circuits in various scenarios.

This micro switch operates based on a lever trigger mechanism. When external force is applied to the hinge roller lever, the internal three split springs will drive the contact set to move. The 2mm contact gap ensures fast disconnection and connection of the circuit. It realizes precise switching action and maintains consistent performance even under frequent actuation conditions.

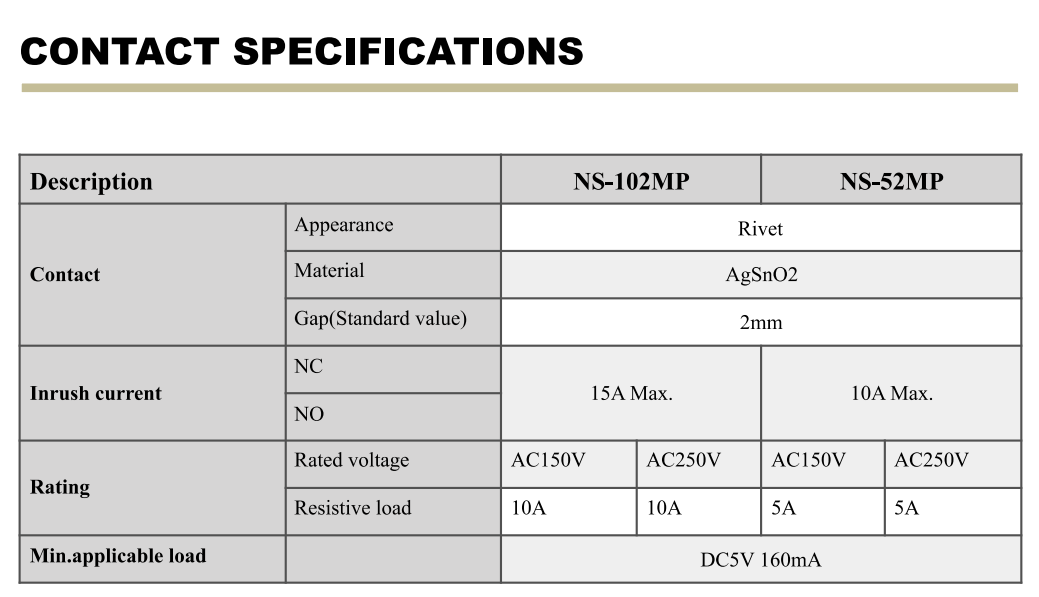

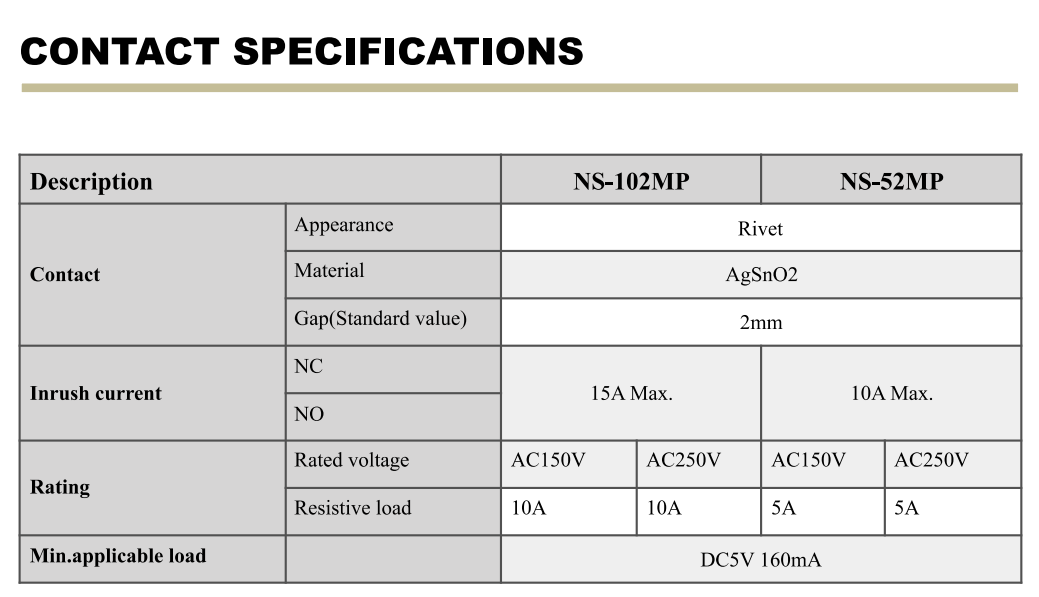

Specifications | NS-102MGP | NS-52MGP |

Contact Material | AgSnO2 | AgSnO2 |

Standard Contact Gap | 2mm | 2mm |

Max. Inrush Current (NC) | 15A | 10A |

Resistive Load (250VAC) | 10A | 5A |

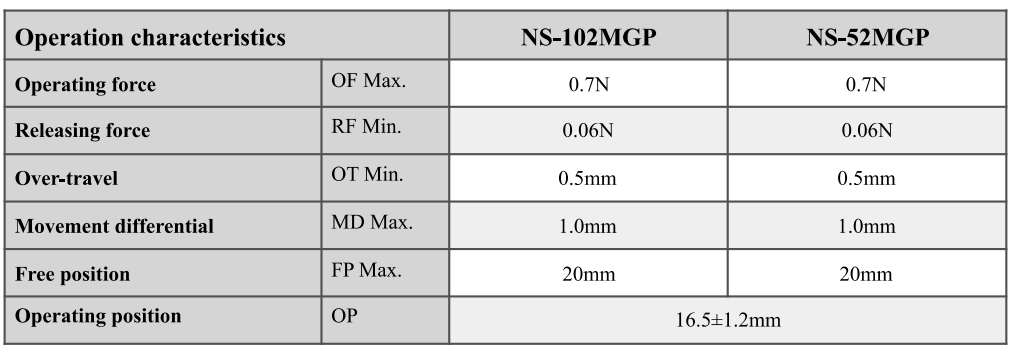

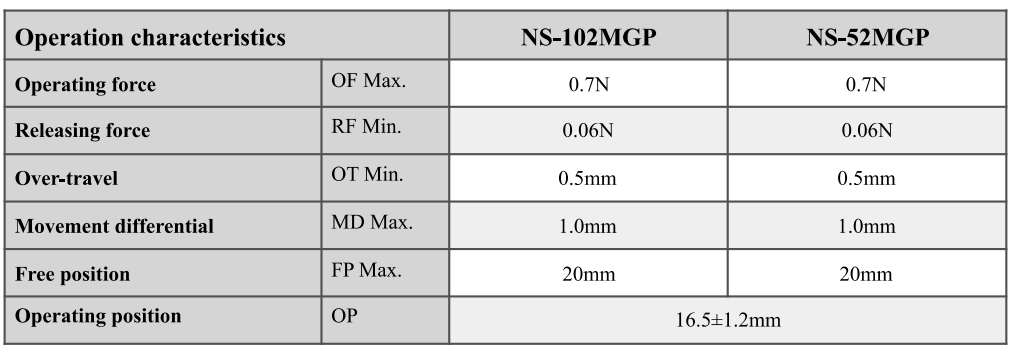

Max. Operating Force | 0.7N | 0.7N |

Min. Releasing Force | 0.06N | 0.06N |

Min. Over-travel | 0.5mm | 0.5mm |

Max. Movement Differential | 1.0mm | 1.0mm |

Contact Form | 1CO (SPDT)/1NC (SPST)/1NO (SPST) | 1CO (SPDT)/1NC (SPST)/1NO (SPST) |

It is widely used in conveyor belt limit control and mechanical arm position detection. The high stability and precise actuation performance can effectively avoid misoperation of equipment.

This micro switch is applied to the door lock control of refrigerators and the cover switch of washing machines. Its durable material ensures a long service life matching the appliance’s lifecycle.

It can be used in seat adjustment systems and window lift control. The wear-resistant contact design adapts to the vibration environment inside the vehicle.

The 2mm standard contact gap enables fast response to trigger signals. It meets the requirements of high-frequency switching scenarios and ensures efficient circuit control.

The three split springs provide balanced tension support. The switch can maintain stable performance in harsh environments and avoid position deviation caused by external interference.

The product uses high-quality AgSnO2 contact material and sturdy shell. It is resistant to wear and tear, reducing the frequency of replacement and lowering the long-term use cost.

Confirm the installation position and fix the switch with matching screws to ensure the hinge roller lever can be fully triggered.

Connect the circuit according to the contact form label (COM, NO, NC) to avoid reverse wiring.

Conduct a trial actuation test to verify the normal on-off of the circuit.

Do not exceed the rated voltage and current to prevent contact burnout.

Regularly check the cleanliness of the contact surface and remove dust and debris in time.

Avoid applying excessive force to the lever to prevent mechanical damage to the internal structure.

The minimum applicable load is DC5V 160mA, which is suitable for low-voltage and low-current control circuits.

Yes, it has a T125 temperature rating, which can work stably in high-temperature scenarios within 125°C.

The main difference lies in the inrush current and resistive load parameters. NS-102MGP supports higher current and is suitable for heavy-load scenarios.

Are you looking for a high-stability micro switch with precise actuation performance? Our 2 mm Contact Gap Three Split Springs Hinge Roller Lever Micro Switch is your ideal choice. Click the Inquire button to get a customized quotation, or directly Add to Basket to place your order. We provide professional technical support to solve all your switching control problems!

The 2 mm Contact Gap Three Split Springs Hinge Roller Lever Micro Switch (model series: NS-102MGP/NS-52MGP) is a high-precision electromechanical switching component produced by CLION. It integrates a hinge roller lever structure, 2mm standard contact gap and three split springs design. The product is engineered to deliver stable and accurate on-off control for electrical circuits in various scenarios.

This micro switch operates based on a lever trigger mechanism. When external force is applied to the hinge roller lever, the internal three split springs will drive the contact set to move. The 2mm contact gap ensures fast disconnection and connection of the circuit. It realizes precise switching action and maintains consistent performance even under frequent actuation conditions.

Specifications | NS-102MGP | NS-52MGP |

Contact Material | AgSnO2 | AgSnO2 |

Standard Contact Gap | 2mm | 2mm |

Max. Inrush Current (NC) | 15A | 10A |

Resistive Load (250VAC) | 10A | 5A |

Max. Operating Force | 0.7N | 0.7N |

Min. Releasing Force | 0.06N | 0.06N |

Min. Over-travel | 0.5mm | 0.5mm |

Max. Movement Differential | 1.0mm | 1.0mm |

Contact Form | 1CO (SPDT)/1NC (SPST)/1NO (SPST) | 1CO (SPDT)/1NC (SPST)/1NO (SPST) |

It is widely used in conveyor belt limit control and mechanical arm position detection. The high stability and precise actuation performance can effectively avoid misoperation of equipment.

This micro switch is applied to the door lock control of refrigerators and the cover switch of washing machines. Its durable material ensures a long service life matching the appliance’s lifecycle.

It can be used in seat adjustment systems and window lift control. The wear-resistant contact design adapts to the vibration environment inside the vehicle.

The 2mm standard contact gap enables fast response to trigger signals. It meets the requirements of high-frequency switching scenarios and ensures efficient circuit control.

The three split springs provide balanced tension support. The switch can maintain stable performance in harsh environments and avoid position deviation caused by external interference.

The product uses high-quality AgSnO2 contact material and sturdy shell. It is resistant to wear and tear, reducing the frequency of replacement and lowering the long-term use cost.

Confirm the installation position and fix the switch with matching screws to ensure the hinge roller lever can be fully triggered.

Connect the circuit according to the contact form label (COM, NO, NC) to avoid reverse wiring.

Conduct a trial actuation test to verify the normal on-off of the circuit.

Do not exceed the rated voltage and current to prevent contact burnout.

Regularly check the cleanliness of the contact surface and remove dust and debris in time.

Avoid applying excessive force to the lever to prevent mechanical damage to the internal structure.

The minimum applicable load is DC5V 160mA, which is suitable for low-voltage and low-current control circuits.

Yes, it has a T125 temperature rating, which can work stably in high-temperature scenarios within 125°C.

The main difference lies in the inrush current and resistive load parameters. NS-102MGP supports higher current and is suitable for heavy-load scenarios.

Are you looking for a high-stability micro switch with precise actuation performance? Our 2 mm Contact Gap Three Split Springs Hinge Roller Lever Micro Switch is your ideal choice. Click the Inquire button to get a customized quotation, or directly Add to Basket to place your order. We provide professional technical support to solve all your switching control problems!