Micro Switch NV

CLION

| Availability: | |

|---|---|

| Quantity: | |

The NV-16Z series micro switch is based on a spring-loaded hinge lever mechanism. When the lever is pushed or released by external force, the internal contacts will be driven to open or close. This mechanism realizes the connection or interruption of the circuit, and ensures the precise and stable switching action of the switch even under high load conditions.

As a high-current high-reliability micro switch, the NV-16Z series has a maximum switching current of up to 21A. It is designed for high-load application scenarios, integrates precise actuation, high sensitivity and long service life, and is suitable for industrial machinery, medical equipment and other fields that require high load-bearing capacity.

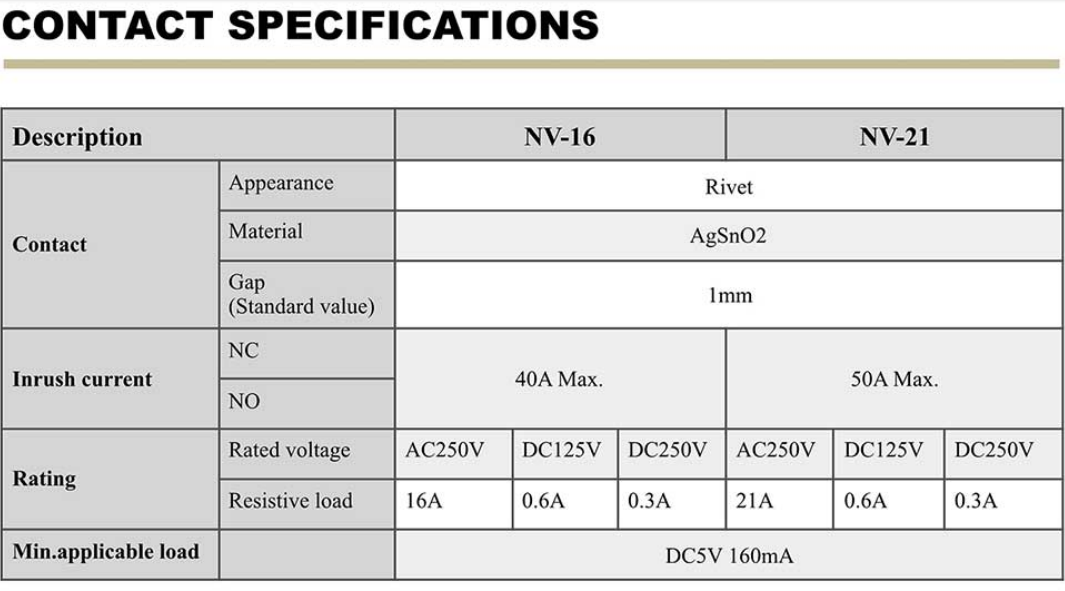

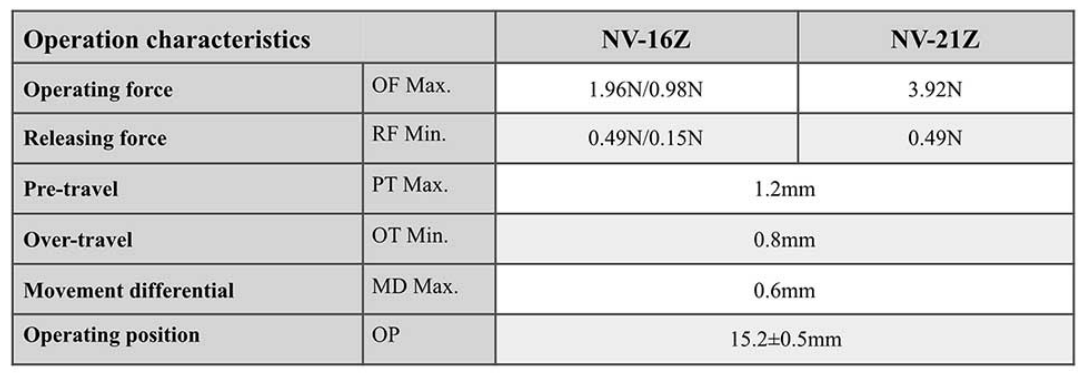

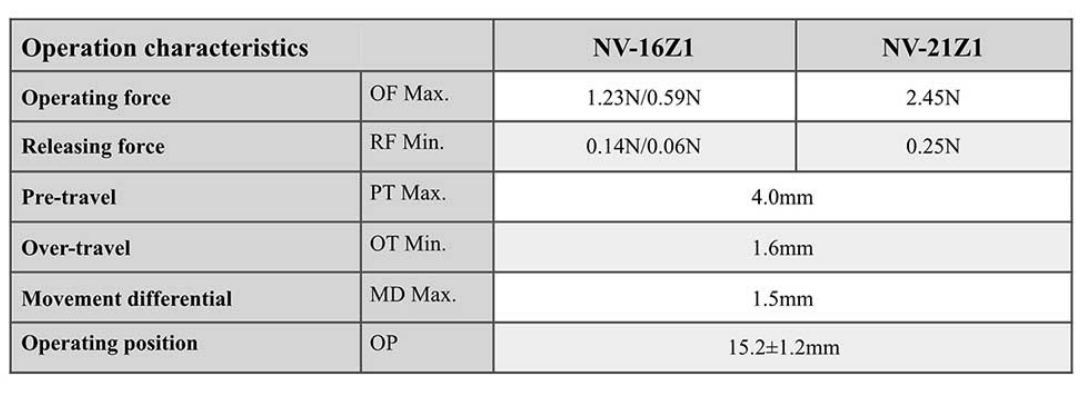

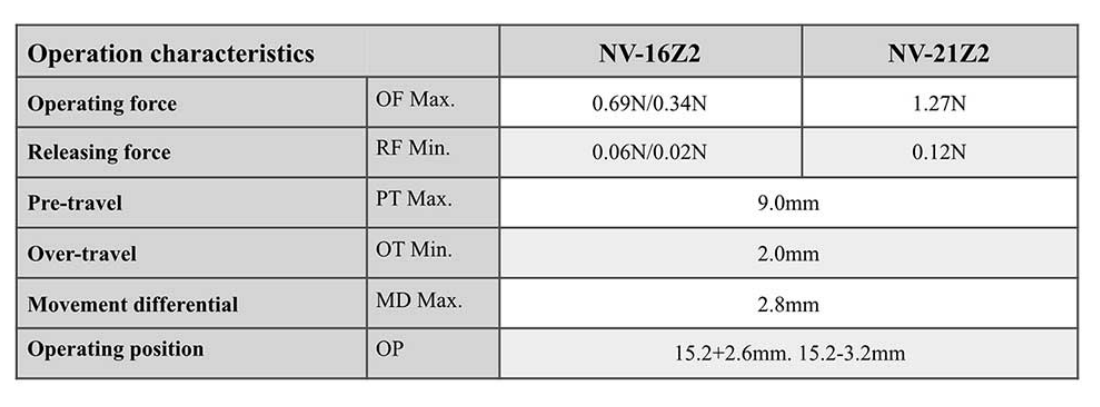

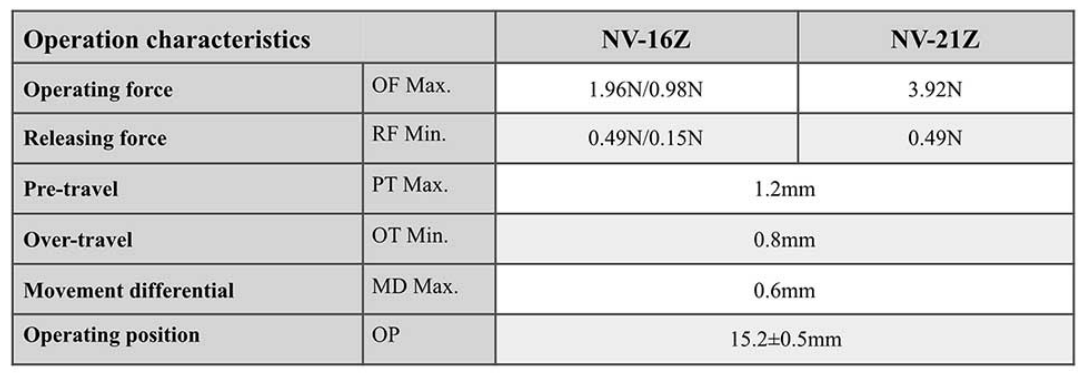

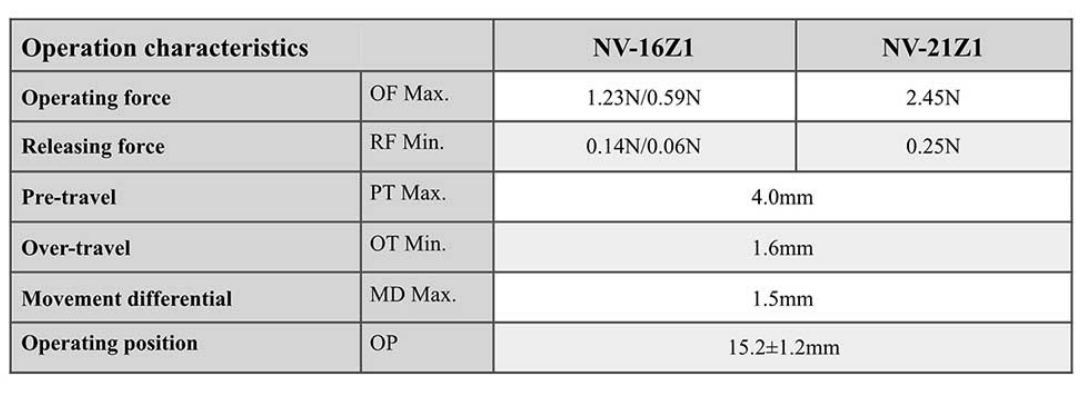

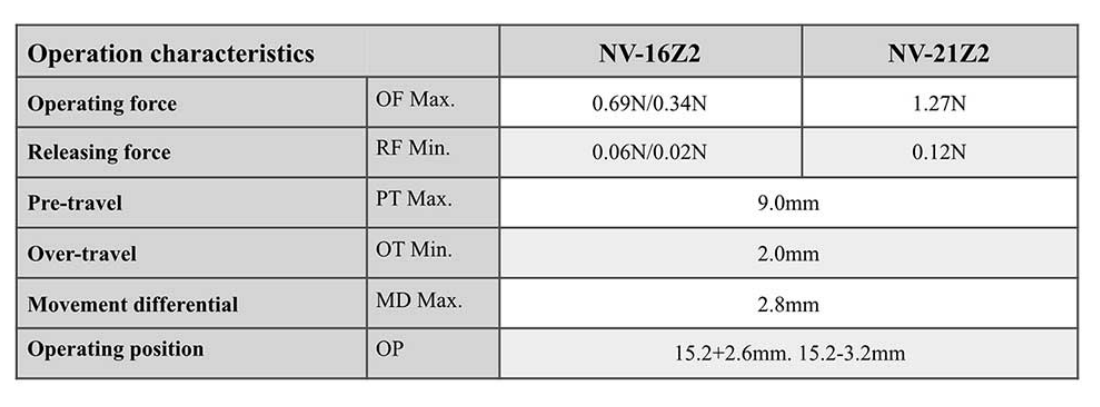

Operation Characteristics | NV-16Z | NV-21Z |

Operating Force (Max.) | 1.96N/0.98N | 3.92N |

Releasing Force (Min.) | 0.49N/0.15N | 0.49N |

Pre-travel (Max.) | 1.2mm | 1.2mm |

Over-travel (Min.) | 0.8mm | 0.8mm |

Movement Differential (Max.) | 0.6mm | 0.6mm |

Operating Position | 15.2±0.5mm | 15.2±0.5mm |

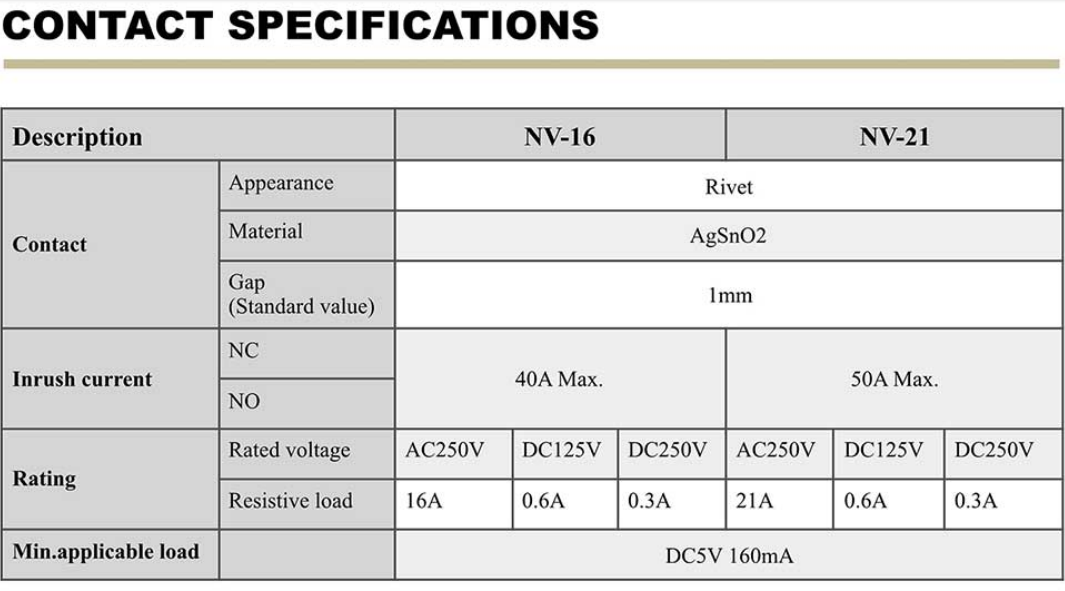

Rated Current & Voltage | 16A 125/250VAC T125 5E4 | 21A 125/250VAC T125 5E4 |

Inrush Current (NO, Max.) | 40A | 50A |

Terminal Type | Three quick-connect terminals (#187, t=0.5) | Three quick-connect terminals (#187, t=0.5) |

The NV-16Z series micro switch can bear high load current, which is suitable for the control system of heavy industrial machinery. It can also be applied to automotive power systems, providing stable circuit switching for high-power components of vehicles.

Its high sensitivity and precise actuation characteristics make it ideal for medical equipment. It can realize delicate switch control in precision medical instruments. In addition, it is used in robotic control systems to sense the position and movement of mechanical arms and ensure the accurate operation of robots.

For high-power household appliances such as air conditioners and washing machines. The switch can withstand the high current when the equipment is started, ensuring the safe and stable operation of the appliances.

With a maximum switching current of up to 21A, the switch can easily handle high-load circuits. It has a strong inrush current resistance, which avoids switch damage caused by instantaneous high current.

The hinge lever design ensures accurate triggering of the switch, which is suitable for application scenarios requiring precise positioning feedback. The switch is made of durable materials, and has passed rigorous testing, which has a long service life and reduces the frequency of replacement.

The series provides multiple models with different lever types (short hinge lever, long hinge lever) and operation force parameters. It can meet the personalized needs of different application scenarios, and has strong versatility.

Determine the installation position according to the equipment requirements, and ensure that the hinge lever has enough movement space.

Fix the switch with matching fasteners, and ensure that the installation surface is flat without tilting.

Connect the circuit through quick-connect terminals, and check the tightness of the connection to prevent poor contact.

Strictly abide by the rated load range. Do not use the switch beyond the rated current and voltage to avoid safety risks.

Avoid corrosive gas and high temperature environment during use to prevent the switch contacts from being oxidized and failing.

Regularly lubricate the hinge lever to ensure the flexibility of the switch movement and maintain the sensitivity of the switch.

The maximum inrush current of the NO contact of the NV-16Z model is 40A, and that of the NV-21Z model is 50A, which can adapt to the instantaneous high current when the equipment is started.

Short hinge levers are suitable for application scenarios with limited movement space, while long hinge levers are suitable for scenarios that need to sense a larger range of movement. You can select the appropriate lever type according to the equipment structure.

Yes. The product is produced by CLION ELECTRIC CO., LTD., and has passed relevant certifications such as CE and TUV, which meets the international quality standards.

Are you in need of a high-current, reliable micro switch for high-load equipment? The NV-16Z series hinge lever micro switch can meet your needs with its excellent performance. Contact our sales team immediately to inquire about customized solutions, or add the product to the shopping cart to place an order quickly!

The NV-16Z series micro switch is based on a spring-loaded hinge lever mechanism. When the lever is pushed or released by external force, the internal contacts will be driven to open or close. This mechanism realizes the connection or interruption of the circuit, and ensures the precise and stable switching action of the switch even under high load conditions.

As a high-current high-reliability micro switch, the NV-16Z series has a maximum switching current of up to 21A. It is designed for high-load application scenarios, integrates precise actuation, high sensitivity and long service life, and is suitable for industrial machinery, medical equipment and other fields that require high load-bearing capacity.

Operation Characteristics | NV-16Z | NV-21Z |

Operating Force (Max.) | 1.96N/0.98N | 3.92N |

Releasing Force (Min.) | 0.49N/0.15N | 0.49N |

Pre-travel (Max.) | 1.2mm | 1.2mm |

Over-travel (Min.) | 0.8mm | 0.8mm |

Movement Differential (Max.) | 0.6mm | 0.6mm |

Operating Position | 15.2±0.5mm | 15.2±0.5mm |

Rated Current & Voltage | 16A 125/250VAC T125 5E4 | 21A 125/250VAC T125 5E4 |

Inrush Current (NO, Max.) | 40A | 50A |

Terminal Type | Three quick-connect terminals (#187, t=0.5) | Three quick-connect terminals (#187, t=0.5) |

The NV-16Z series micro switch can bear high load current, which is suitable for the control system of heavy industrial machinery. It can also be applied to automotive power systems, providing stable circuit switching for high-power components of vehicles.

Its high sensitivity and precise actuation characteristics make it ideal for medical equipment. It can realize delicate switch control in precision medical instruments. In addition, it is used in robotic control systems to sense the position and movement of mechanical arms and ensure the accurate operation of robots.

For high-power household appliances such as air conditioners and washing machines. The switch can withstand the high current when the equipment is started, ensuring the safe and stable operation of the appliances.

With a maximum switching current of up to 21A, the switch can easily handle high-load circuits. It has a strong inrush current resistance, which avoids switch damage caused by instantaneous high current.

The hinge lever design ensures accurate triggering of the switch, which is suitable for application scenarios requiring precise positioning feedback. The switch is made of durable materials, and has passed rigorous testing, which has a long service life and reduces the frequency of replacement.

The series provides multiple models with different lever types (short hinge lever, long hinge lever) and operation force parameters. It can meet the personalized needs of different application scenarios, and has strong versatility.

Determine the installation position according to the equipment requirements, and ensure that the hinge lever has enough movement space.

Fix the switch with matching fasteners, and ensure that the installation surface is flat without tilting.

Connect the circuit through quick-connect terminals, and check the tightness of the connection to prevent poor contact.

Strictly abide by the rated load range. Do not use the switch beyond the rated current and voltage to avoid safety risks.

Avoid corrosive gas and high temperature environment during use to prevent the switch contacts from being oxidized and failing.

Regularly lubricate the hinge lever to ensure the flexibility of the switch movement and maintain the sensitivity of the switch.

The maximum inrush current of the NO contact of the NV-16Z model is 40A, and that of the NV-21Z model is 50A, which can adapt to the instantaneous high current when the equipment is started.

Short hinge levers are suitable for application scenarios with limited movement space, while long hinge levers are suitable for scenarios that need to sense a larger range of movement. You can select the appropriate lever type according to the equipment structure.

Yes. The product is produced by CLION ELECTRIC CO., LTD., and has passed relevant certifications such as CE and TUV, which meets the international quality standards.

Are you in need of a high-current, reliable micro switch for high-load equipment? The NV-16Z series hinge lever micro switch can meet your needs with its excellent performance. Contact our sales team immediately to inquire about customized solutions, or add the product to the shopping cart to place an order quickly!